Tofu

Cassava

Millet

Crystal

CAT LITTER MANUFACTURER

CAT LITTER

Choose Your Cat Litter Now

Top Selling Products

-

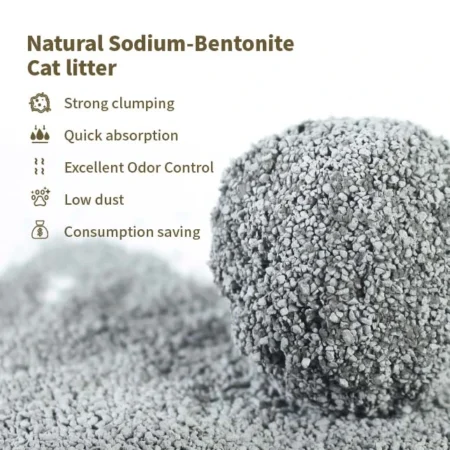

Natural Sodium-Bentonite Cat Litter

Rated 5.00 out of 5(2 reviews) -

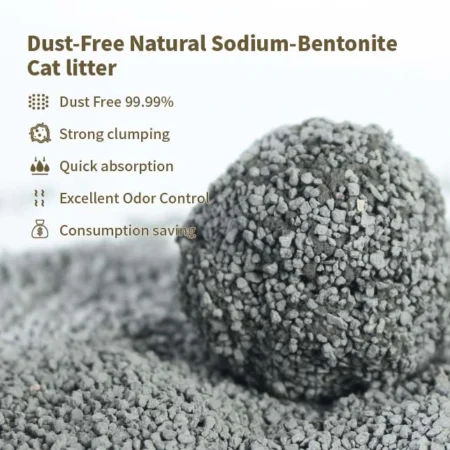

Dust-Free Natural Sodium-Bentonite Cat Litter

Rated 5.00 out of 5(2 reviews) -

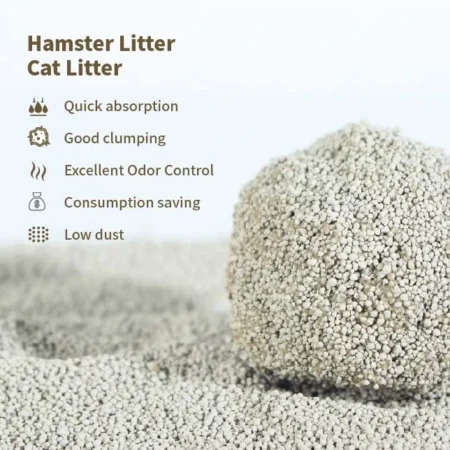

Hamster Litter Cat Litter

Rated 5.00 out of 5(2 reviews)

On Sale Products

-

Broken Tofu Mixed Zeolite Cat Litter

Rated 5.00 out of 5(2 reviews) -

Broken Tofu Cat Litter

Rated 5.00 out of 5(2 reviews) -

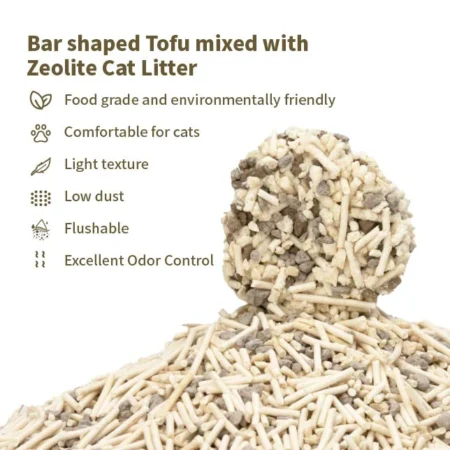

Bar Tofu Mixed Zeolite Cat litter

Rated 5.00 out of 5(2 reviews)

Mixture

Usual

Type More then

Function

Usual

Color

Tofu litter available in 8 colors. We can do all the grain colors you want.

Fragrance

With over 14 scents to choose from, we have all the scents you want.

With over 14 scents to choose from, we have all the scents you want.

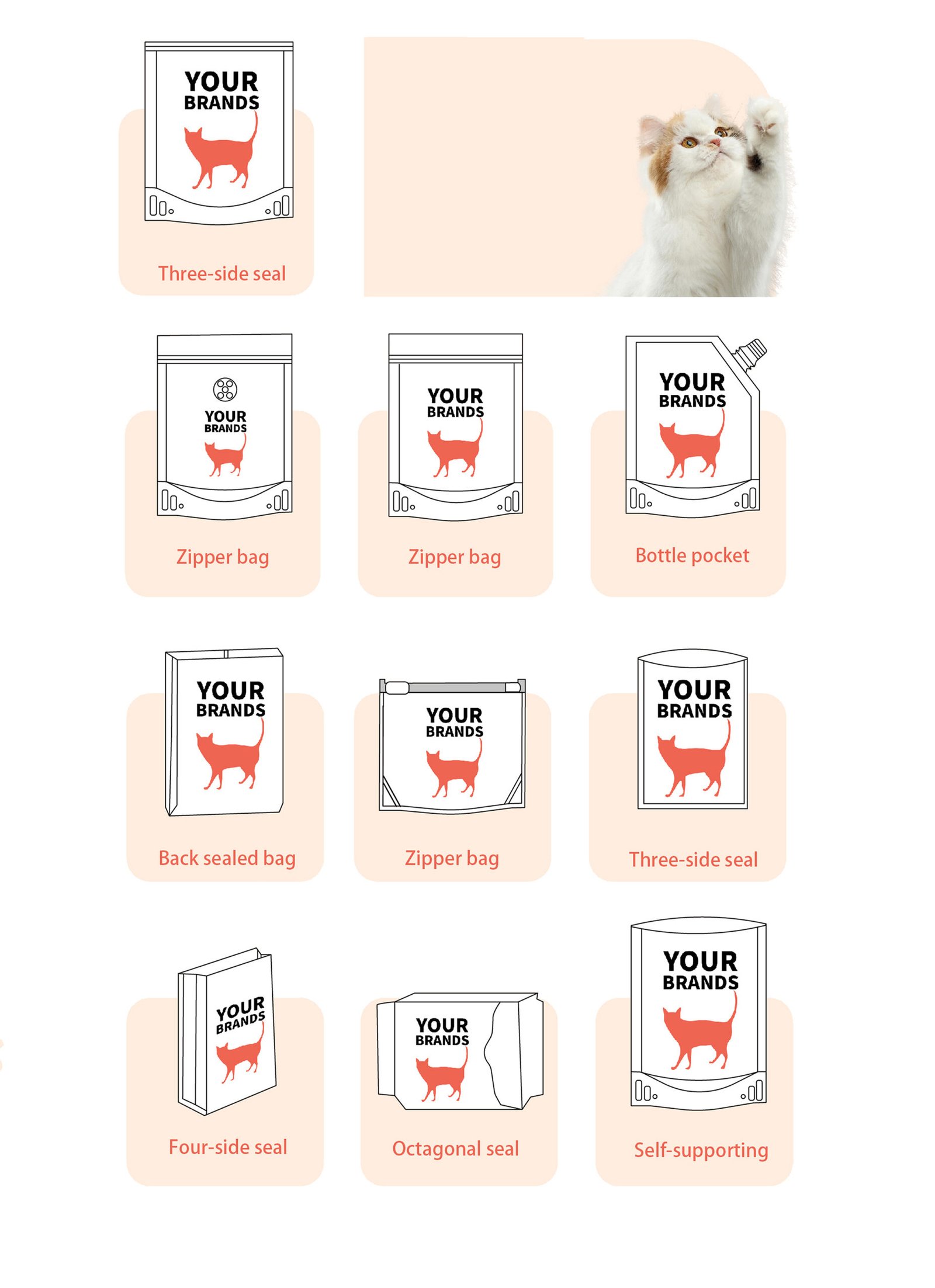

Package

You can choose from existing packing designs

You can choose existing packing designs

We can help you with a brand new design

We can help you with a brand new design

You can customize it if you want

Industry Leading Cat Litter Manufacturer

We have more than 20 years of professional customization experience and we never stop innovating. We have more than 6 Raymond machines, 300,000 monthly output, more than 24 automated production machines, more than 185 acres of land area.Whether it is new products, new formulations or new packaging designs, we are constantly creating.

Factory Display

Cat Litter Process

Bentonite raw material is sent to Raymond machine for pulverization and processed into 200 mesh powder. This step is to ensure uniformity and fineness of the litter particles.

The crushed bentonite powder was fed into a granulator for granulation. Through the action of a granulator, the powder is made into cat litter particles of a certain size. During the granulation process, clean water needs to be added drip by drip evenly to control the size and shape of the litter particles. Generally, the particle size of the granulated finished product is set to 0.8 to 5mm.

The granulated wet litter was fed into a roller dryer for dehydration and drying. The water content of cat litter was reduced to less than 6% by drying and dewatering at high temperatures. After drying, cat litter needs to be cooled naturally to remove excess heat and moisture.